Location: Home / Cases / Classic Case

Edit:SO SURE browse:1161 Datetime:2021.08.04

Shengbang Group Co., Ltd. (Shengbang injection molding machine) is a national spark and torch project enterprise and a national high-tech enterprise. It is a major manufacturer specializing in the production of high-performance injection molding machines and engineering hydraulic parts in China.

Project background:

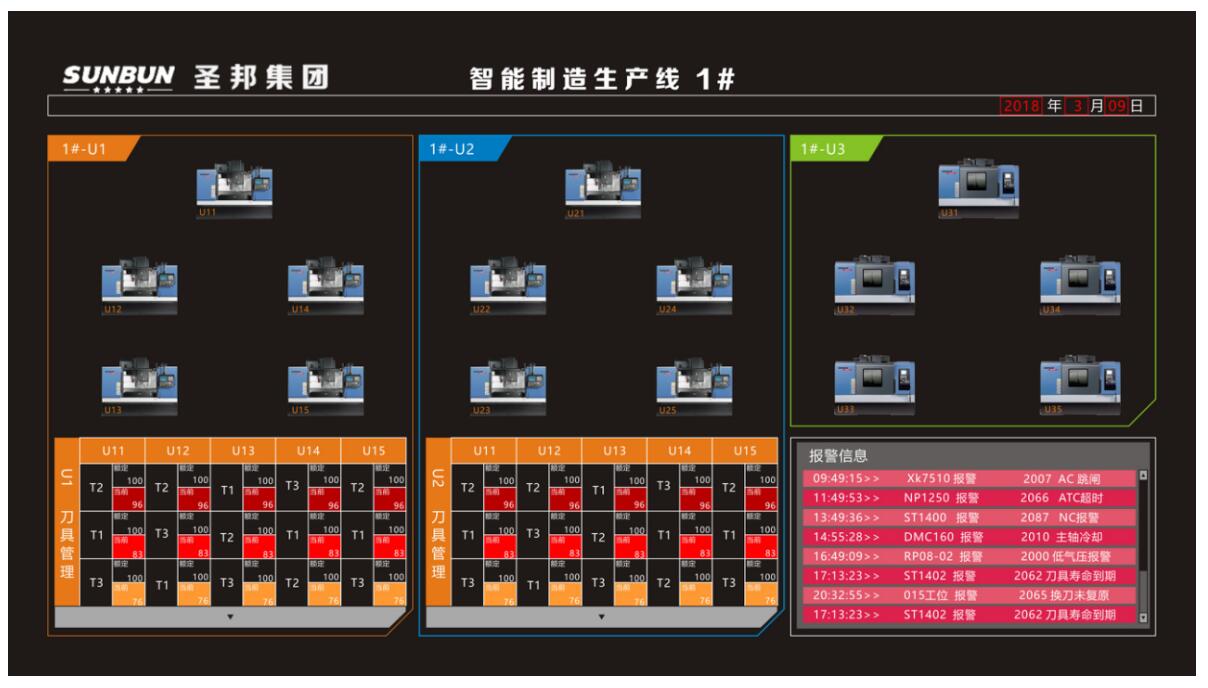

At present, Germany, Japan and other international leading multi axis machining centers and a series of complete sets of CNC machining equipment, CMM, spectrum analyzer, roundness meter and other high-precision detection and inspection and metal material analysis instruments are introduced to implement a production information platform that can be seamlessly integrated with the existing information system of the enterprise and the workshop site, so as to improve the operation efficiency of the factory Reduce production and operation costs and improve competitiveness.

Using the modern IMS / DNC / MDC system, the whole manufacturing process can be completely transparent, the current status can be mastered, the historical data can be analyzed, and the future production can be reasonably planned. On the one hand, the implementation system realizes the vertical integration between production management and business management, and eliminates the insurmountable gap between workshop site management based on equipment, station, material flow and personnel operation activities and business management based on resource management; On the other hand, it ensures the smooth flow of information between different functional areas of workshop on-site management, plays an important role in production data collection, production evaluation and production planning, and realizes the horizontal integration of workshop management, so as to improve capacity utilization and product quality.

Project content:

Equipment data management

Equipment data communication

Equipment real-time data acquisition

Equipment data analysis

Tool life management

Quality Assurance