Based on the workshop manufacturing data visualization and asset management system, collect, report and chart the detailed manufacturing data and process of the workshop in real time. According to the characteristics of discrete processing industry, MDC provides more professional analysis and processing in data mining of collected data.

Customized data processing and rich graphical report display functions cover all aspects of workshop application, and make statistics and Analysis on key data related to equipment and production, such as startup rate, spindle operation rate, spindle load rate, NC operation rate, failure rate, equipment comprehensive utilization rate (OEE), equipment productivity, parts qualification rate, quality percentage, etc.

On this basis, accumulate the problems and solutions in the daily work of the enterprise, so that the enterprise can find the direction and methods of technological innovation. Implement advanced management ideas such as spot inspection system, and build enterprise decision-making and innovation activities on data from the grass-roots level.

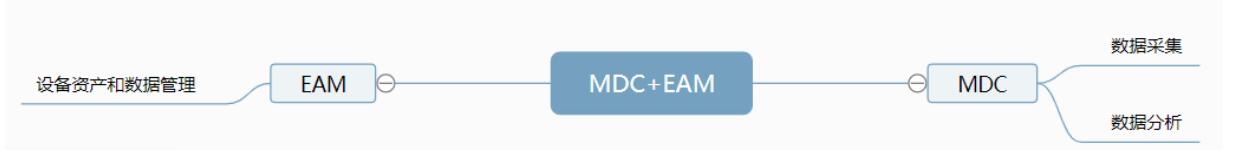

Data acquisition + asset management provides a strong guarantee for efficient production and enables enterprise asset management.

MDC:

Realize the real-time monitoring of the operation of the machine tool, such as the monitoring of on-off, processing and maintenance. Understand the actual state of the machine tool in real time to facilitate production planning; At the same time, the machine tool processing and fault information are obtained to facilitate the maintenance of the machine tool.

Using equipment data can provide intelligent decision-making basis for production management, and provide data basis for workshop to reasonably arrange production and improve production efficiency.

The tool life can be monitored to achieve life early warning and tool change in advance to avoid unnecessary loss.

Remote monitoring and collection of equipment status can realize the statistics, analysis, evaluation and automatic calculation of utilization efficiency of NC equipment, display statistical charts in rich forms, generate reports, and provide the results to relevant departments or systems for use, so as to improve production efficiency and reduce production costs.

Function description points: equipment data acquisition mode and content, real-time display of equipment data acquisition, collection of equipment comprehensive operation efficiency, electronic map, data statistical analysis (display of multiple dimensions), data acquisition characteristics, system integration (integration of MDC system and MES system)

EAM:

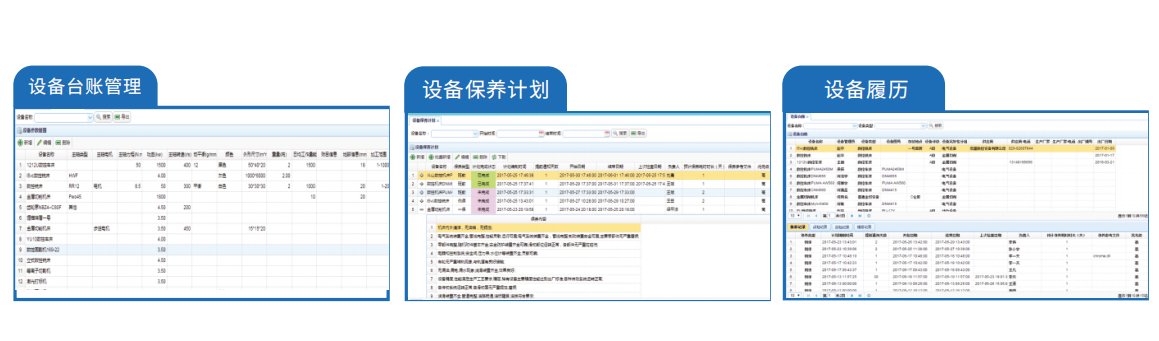

Quantify equipment asset management through EAM management system and standardize its workflow; Realize asset management informatization and more effectively allocate production equipment, personnel and other resources.

With the help of the system, each maintenance manager can manage more equipment, improve the safety of workers, promote the implementation of procedures and reduce shutdown time.

Establish a clear and dynamic equipment database, improve equipment availability and reliability, control maintenance and repair costs, prolong equipment life cycle, reduce spare parts inventory and cost, help enterprises better implement ISO9000, comply with the laws and regulations of industry and government departments, improve effective working hours, reduce equipment downtime and increase equipment use efficiency.