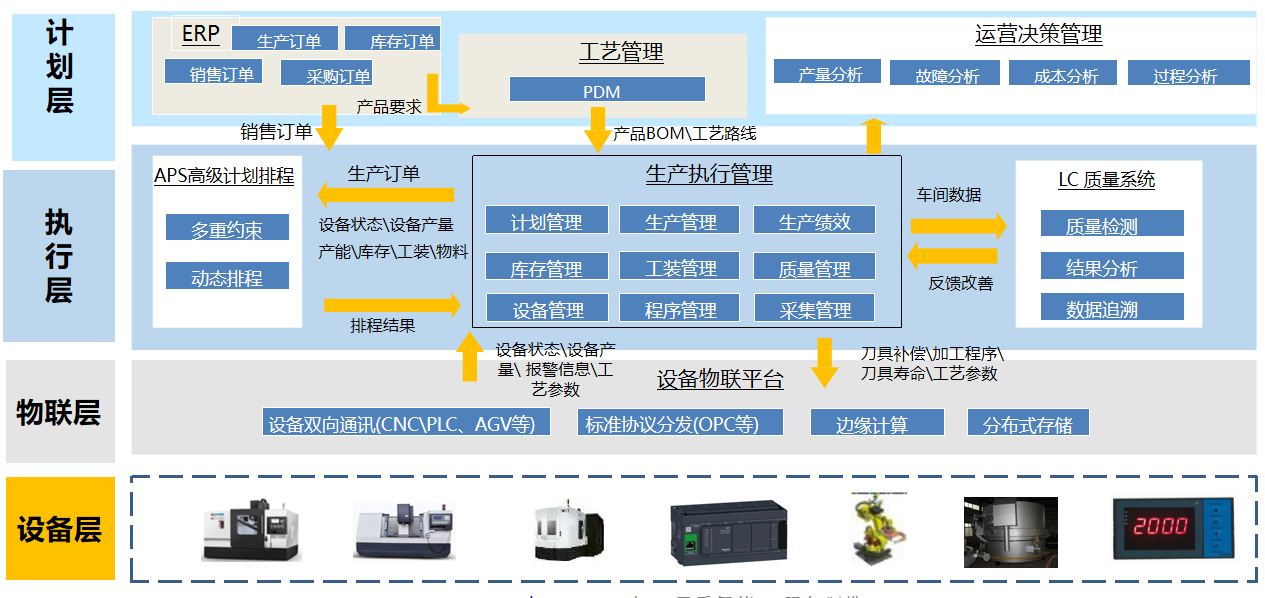

In recent years, with the proposal of new production modes such as JIT (just in time), BTO (order oriented production) and higher requirements for product quality from customers and the market, MES has been rediscovered and valued. Meanwhile, an invincible position of the network economy bubble has led enterprises to realize that they should enhance their competitiveness from the most basic production management. That is, only when data information is removed from product level (basic automation level), they pass through the operation control level and serve the management level, and the continuous information flow can be achieved to achieve enterprise information integration, so that enterprises can win an invincible position in the increasingly fierce competition. MES is rapidly and widely used abroad.

Manufacturing execution system (MES) aims to improve the execution ability of enterprises and has irreplaceable functions. In the process industry in the competitive environment, enterprises should distinguish the objectives and functions of different manufacturing management systems, clarify the positioning of MES in the integrated system, and pay attention to the accuracy and timeliness of information, standardize processes, use tools and management innovation, According to the MES maturity model, analyze its own execution ability, and implement the MES system step by step according to the three stages of information integration, transaction processing and manufacturing intelligence, so as to give full play to the role of enterprise informatization, improve the competitiveness of enterprises and bring expected benefits to enterprises.

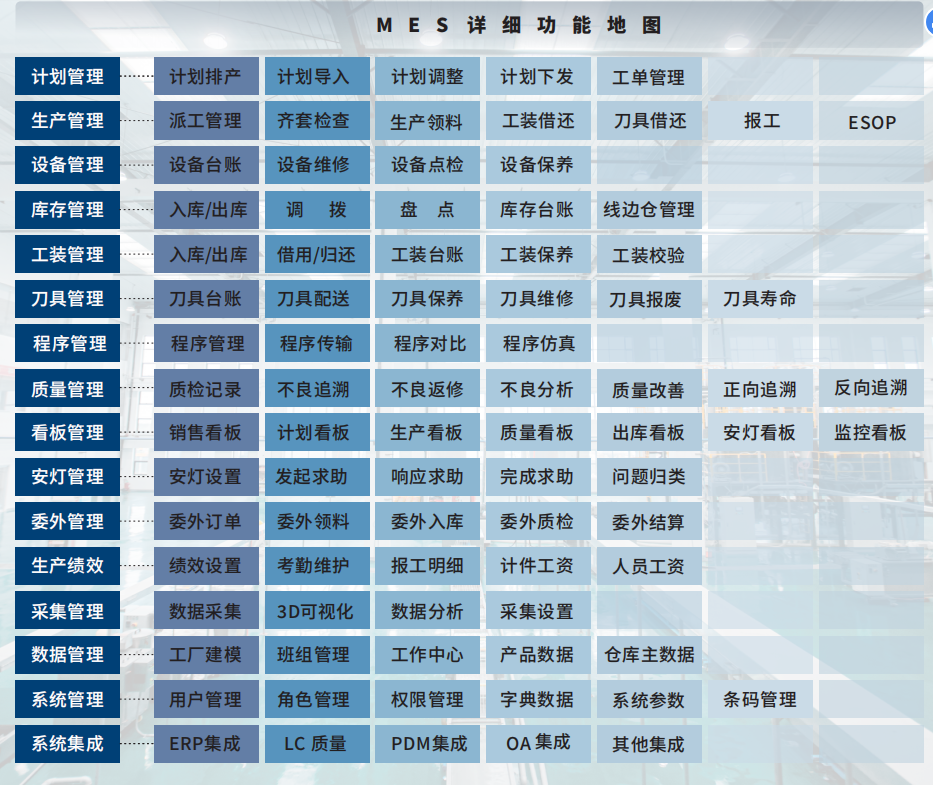

MES system is a production information management system for the workshop executive layer of manufacturing enterprises. MES can provide enterprises with management modules including manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, human resource management, work center / equipment management, tool and tooling management, procurement management, cost management, project Kanban management, production process control, bottom-level data integration and analysis, and upper-level data integration and decomposition, Create a solid, reliable, comprehensive and feasible manufacturing collaborative management platform for enterprises.